Description

Outdoor WPC Wall Cladding Factory: Innovations in Automation, Sustainability, and Design

Introduction

The outdoor WPC (Wood Plastic Composite) wall cladding industry is experiencing a significant transformation driven by technological advancements. These advancements not only enhance the efficiency of production processes but also contribute to sustainability and aesthetic improvements. This article delves into the latest innovations in outdoor WPC wall cladding factories, focusing on automation, sustainable practices, and design enhancements that improve both functionality and visual appeal.

Automation in Production Processes

One of the most notable trends in modern outdoor WPC wall cladding factories is the integration of automation. Advanced robotic systems and automated machinery are being employed to streamline production lines. These technologies reduce human error, increase output speed, and ensure consistent quality. For instance, automated cutting machines can precisely cut materials to size with minimal waste, while robotic arms handle heavy lifting and placement tasks. Such advancements not only boost productivity but also create safer working environments for employees. According to a study by the International Journal of Advanced Robotic Systems, these automated systems can significantly enhance manufacturing efficiency (IJARS, 2020).

Sustainable Practices

Environmental consciousness is increasingly influencing the design and production of outdoor WPC wall cladding. Manufacturers are adopting sustainable practices to minimize their ecological footprint. This includes using recycled plastics and wood fibers, which reduce reliance on virgin materials and lower carbon emissions. Additionally, energy-efficient equipment and renewable energy sources like solar power are being integrated into factory operations. These efforts align with global sustainability goals and appeal to environmentally conscious consumers. The European Union’s commitment to reducing plastic waste through initiatives like the Circular Economy Action Plan highlights the importance of such sustainable practices (EU Circular Economy Action Plan).

Design Improvements

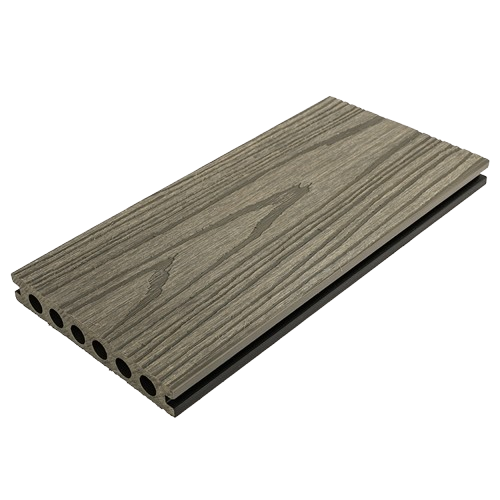

Modern outdoor WPC wall cladding is not just about functionality; it also emphasizes aesthetic appeal. Innovations in design include a wider range of colors, textures, and patterns that mimic natural wood grain or create unique artistic effects. Advanced printing techniques and surface treatments allow for intricate designs that can be customized to suit various architectural styles. Furthermore, improvements in weather resistance and UV protection ensure that these claddings maintain their appearance over time, even under harsh environmental conditions. A report by MarketsandMarkets highlights the growing demand for aesthetically pleasing yet durable outdoor WPC products (MarketsandMarkets, 2021).

Conclusion

The outdoor WPC wall cladding industry is witnessing a transformative period marked by technological advancements in automation, sustainability, and design. These innovations not only enhance production efficiency and product durability but also contribute to environmental conservation and aesthetic enhancement. As manufacturers continue to embrace these changes, we can expect further advancements that will shape the future of this industry.

Reference

International Journal of Advanced Robotic Systems, “Robotic Systems in Manufacturing: A Comprehensive Review,” 2020.

European Commission – Circular Economy Action Plan.

MarketsandMarkets – Wood Plastic Composite Market, 2021.

Baoding Plastroy WPC Products

Why Choose Plastory?

Baoding Plastory New Materials Co., Ltd. is a manufacturer of decorative materials with over 9 years of experience and 56 separate production lines.

Currently, our annual production exceeds 30,000 tons, with products exported to more than 50 countries worldwide.

Plastory is the drafting unit of the WPC National Standards and has obtained certifications such as REACH, ASTM, CE, and FSC. Plastory is dedicated to maintaining consistent quality, focusing on details, and prioritizing customer satisfaction.

Our factory is located in Baoding, Hebei Province, China, with a prime location and convenient transportation access. Baoding is approximately a 1.5-hour drive from Beijing Capital International Airport and just 2 hours away from Tianjin Port, making it easy for global clients to visit and facilitating efficient shipping of goods. Our facility spans a large area, equipped with advanced production equipment and modern testing facilities to ensure that every batch of products meets the highest quality standards.

We warmly welcome clients from around the world to visit our factory, where you can see our production processes firsthand and experience our product quality. Please feel free to reach out to us—we are committed to providing you with the best products and services.

Kindly get in touch with us to request a product catalogue.

Reviews

There are no reviews yet.