Description

Installation Tips for Wood Plastic Composite Decking in Singapore

Introduction

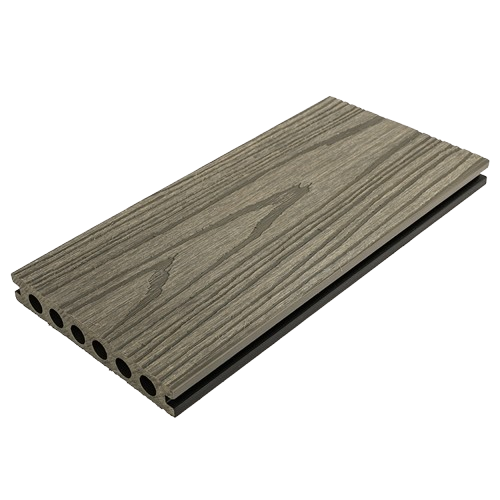

Wood Plastic Composite (WPC) decking has gained popularity as a low-maintenance alternative to traditional wooden decks in Singapore. This eco-friendly material is made from recycled plastics and wood fibers, offering durability and resistance against moisture, pests, and rot. Installing WPC decking can be a rewarding project if done correctly. This article will guide you through the step-by-step process of installing WPC decking in Singapore, highlighting essential tools, common pitfalls to avoid, and recommendations for sealing and maintaining your deck.

Necessary Tools and Materials

To successfully install a WPC deck, you will need several key tools and materials. These include:

- A circular saw or jigsaw for cutting the composite boards to size.

- A drill with various bits for attaching the boards and securing railings.

- Screws specifically designed for composite materials.

- Composite deck joist hangers and brackets for structural support.

- A level and measuring tape for ensuring accuracy in your measurements.

- Sealant or paint designed for WPC materials to protect against weathering.

Step-by-Step Installation Process

Planning and Preparation

Before beginning the installation, ensure that your site is properly prepared. Clear the area where the deck will be built, ensuring it is level and free of debris. Check local building codes and regulations, and consider consulting with a professional if you are unsure about any aspect of the project.

Installing the Frame

The first step in installing your WPC deck is setting up the frame. Use treated lumber to create the perimeter and support beams, ensuring they are level and secure. Attach the composite joists at regular intervals using the appropriate hardware. Remember to leave enough space between the joists to accommodate the composite boards.

Installing the Composite Boards

Begin laying out the composite boards on top of the joists, starting from one end of the deck. Use screws designed for composite materials to attach each board securely. Ensure that there is a small gap between each board to allow for expansion and contraction due to temperature changes. This will prevent warping and buckling over time.

Common Mistakes to Avoid

Several common mistakes can lead to subpar results when installing a WPC deck. Here are some things to watch out for:

- Not leaving enough space between boards for expansion.

- Using incorrect screws that may damage the composite material.

- Over-tightening screws, which can cause the boards to crack.

- Ignoring proper drainage, leading to water accumulation beneath the deck.

Sealing and Maintenance Recommendations

Once installed, your WPC deck will require minimal maintenance compared to traditional wood decks. However, applying a sealant or paint designed for WPC materials can enhance its appearance and longevity. Regular cleaning with mild soap and water is sufficient, but you should inspect the deck periodically for signs of wear and repair any damaged areas promptly.

Conclusion

Installing a Wood Plastic Composite deck in Singapore can be a satisfying DIY project if approached with care and attention to detail. By following these steps and avoiding common pitfalls, you can create a beautiful outdoor living space that stands the test of time. Remember to choose high-quality materials and consult professionals if needed to ensure a successful installation.

Reference

How to Install Composite Decking, Home Depot

Baoding Plastroy WPC Products

Why Choose Plastory?

Baoding Plastory New Materials Co., Ltd. is a manufacturer of decorative materials with over 9 years of experience and 56 separate production lines.

Currently, our annual production exceeds 30,000 tons, with products exported to more than 50 countries worldwide.

Plastory is the drafting unit of the WPC National Standards and has obtained certifications such as REACH, ASTM, CE, and FSC. Plastory is dedicated to maintaining consistent quality, focusing on details, and prioritizing customer satisfaction.

Our factory is located in Baoding, Hebei Province, China, with a prime location and convenient transportation access. Baoding is approximately a 1.5-hour drive from Beijing Capital International Airport and just 2 hours away from Tianjin Port, making it easy for global clients to visit and facilitating efficient shipping of goods. Our facility spans a large area, equipped with advanced production equipment and modern testing facilities to ensure that every batch of products meets the highest quality standards.

We warmly welcome clients from around the world to visit our factory, where you can see our production processes firsthand and experience our product quality. Please feel free to reach out to us—we are committed to providing you with the best products and services.

Kindly get in touch with us to request a product catalogue.

Reviews

There are no reviews yet.