Description

Performance Comparison: Solid vs Hollow Composite Decking

Introduction

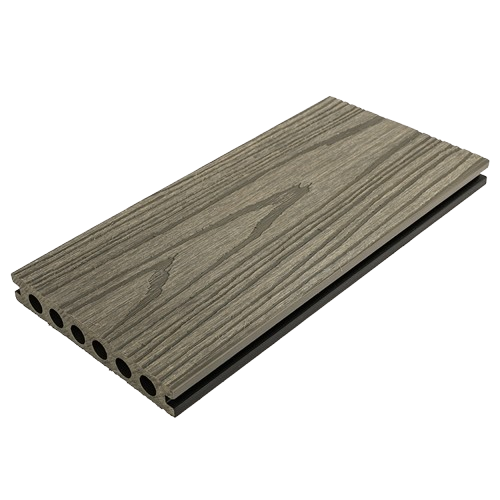

Composite decking has become an increasingly popular choice for outdoor living spaces due to its durability, low maintenance, and aesthetic appeal. Among the different types of composite decking, solid and hollow options are two prevalent choices. While both materials offer significant advantages over traditional wood, understanding the differences in their performance can help homeowners make informed decisions. This article delves into a detailed analysis comparing solid and hollow composite decking, supported by data from tests and expert opinions.

Strength and Durability

One of the primary considerations when choosing composite decking is strength and durability. Solid composite decking is known for its robust structure, which makes it less prone to bending or sagging under heavy loads. According to a study conducted by the Composite Panel Association (CPA), solid composite decking can withstand up to 1,500 pounds per square inch (psi) without showing significant deformation (Composite Panel Association). On the other hand, hollow composite decking, while still durable, tends to be slightly more flexible. However, advancements in manufacturing techniques have improved the load-bearing capacity of hollow composites, with some models now capable of supporting up to 1,200 psi.

Maintenance and Cost

Maintenance requirements and cost are also crucial factors when selecting composite decking. Solid composite decking generally requires less maintenance compared to hollow versions due to its uniform construction. The absence of hollow spaces means there is no risk of water accumulation, which can lead to mold and mildew growth in hollow composites. Additionally, solid composites often come at a higher initial cost but may prove more economical in the long run due to lower maintenance needs. Hollow composite decking, although cheaper upfront, might incur additional costs for regular cleaning and inspection to prevent moisture-related issues.

Environmental Impact

Another important aspect to consider is the environmental impact of composite decking materials. Both solid and hollow composites contribute to sustainability efforts as they are made from recycled plastics and wood fibers. However, solid composites tend to use more material, which could be seen as having a slightly larger carbon footprint. Conversely, hollow composites use less raw material, making them a greener option in terms of resource consumption. Nonetheless, the overall environmental benefits of using composite materials over traditional wood remain significant, reducing deforestation and promoting recycling.

Conclusion

In conclusion, both solid and hollow composite decking offer distinct advantages that cater to different homeowner preferences and needs. Solid composite decking excels in strength and durability, making it ideal for high-traffic areas and heavy loads. Meanwhile, hollow composite decking provides a cost-effective alternative with reduced material usage, suitable for environments where moisture management is critical. Ultimately, the choice between solid and hollow composite decking should be based on specific project requirements and personal priorities.

Reference

Baoding Plastroy WPC Products

Why Choose Plastory?

Baoding Plastory New Materials Co., Ltd. is a manufacturer of decorative materials with over 9 years of experience and 56 separate production lines.

Currently, our annual production exceeds 30,000 tons, with products exported to more than 50 countries worldwide.

Plastory is the drafting unit of the WPC National Standards and has obtained certifications such as REACH, ASTM, CE, and FSC. Plastory is dedicated to maintaining consistent quality, focusing on details, and prioritizing customer satisfaction.

Our factory is located in Baoding, Hebei Province, China, with a prime location and convenient transportation access. Baoding is approximately a 1.5-hour drive from Beijing Capital International Airport and just 2 hours away from Tianjin Port, making it easy for global clients to visit and facilitating efficient shipping of goods. Our facility spans a large area, equipped with advanced production equipment and modern testing facilities to ensure that every batch of products meets the highest quality standards.

We warmly welcome clients from around the world to visit our factory, where you can see our production processes firsthand and experience our product quality. Please feel free to reach out to us—we are committed to providing you with the best products and services.

Kindly get in touch with us to request a product catalogue.

Reviews

There are no reviews yet.