Description

The Future of Door Manufacturing: WPC Door Frame Production Line

Introduction to WPC Door Frames

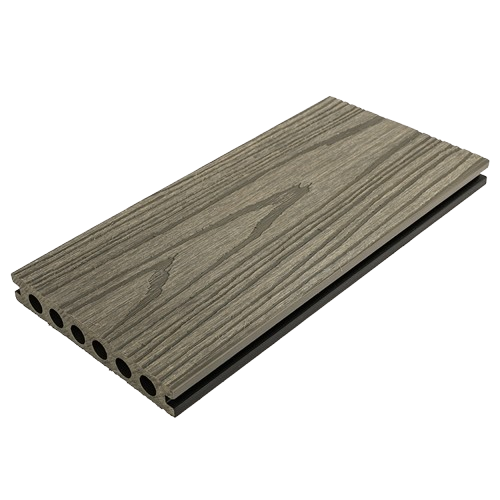

Wood Plastic Composite (WPC) door frames are revolutionizing the construction industry with their durability, low maintenance, and eco-friendly properties. These door frames are made from a blend of wood fibers and thermoplastics, providing a sustainable alternative to traditional wooden or metal frames. The advent of advanced manufacturing technologies has enabled the development of dedicated WPC door frame production lines, streamlining the process and enhancing efficiency.

Technological Advancements in WPC Door Frame Production Lines

The integration of robotics and smart systems into WPC door frame production lines marks a significant leap in the manufacturing sector. Robotics allows for precise cutting, shaping, and assembly processes, reducing human error and increasing productivity. Smart systems, on the other hand, provide real-time monitoring and control over the production process, ensuring consistency and quality. These advancements have not only improved the output but also reduced costs and environmental impact.

Key Features of WPC Door Frame Production Lines

One of the key features of modern WPC door frame production lines is the use of automated robotic arms. These arms can handle heavy materials and perform intricate operations with high precision. They are programmed to follow exact specifications, ensuring uniformity across all products. Additionally, these robots can work continuously without breaks, leading to increased production speed and capacity.

Smart systems play an equally crucial role in optimizing the production process. These systems use sensors and data analytics to monitor every step of the manufacturing process. They can detect anomalies and adjust settings in real time, preventing defects and maintaining product quality. Furthermore, these smart systems can integrate with enterprise resource planning (ERP) software, allowing for seamless coordination between different departments and stages of production.

Conclusion

The future of door manufacturing lies in the adoption of WPC door frame production lines equipped with advanced robotics and smart systems. These innovations not only enhance the efficiency and quality of production but also contribute to sustainability by using eco-friendly materials. As technology continues to evolve, we can expect even more sophisticated solutions that will further transform the industry.

Reference

Advances in Robotic Systems for Wood Plastic Composite Manufacturing

Integration of Smart Systems in Modern Manufacturing Processes

Baoding Plastroy WPC Products

Why Choose Plastory?

Baoding Plastory New Materials Co., Ltd. is a manufacturer of decorative materials with over 9 years of experience and 56 separate production lines.

Currently, our annual production exceeds 30,000 tons, with products exported to more than 50 countries worldwide.

Plastory is the drafting unit of the WPC National Standards and has obtained certifications such as REACH, ASTM, CE, and FSC. Plastory is dedicated to maintaining consistent quality, focusing on details, and prioritizing customer satisfaction.

Our factory is located in Baoding, Hebei Province, China, with a prime location and convenient transportation access. Baoding is approximately a 1.5-hour drive from Beijing Capital International Airport and just 2 hours away from Tianjin Port, making it easy for global clients to visit and facilitating efficient shipping of goods. Our facility spans a large area, equipped with advanced production equipment and modern testing facilities to ensure that every batch of products meets the highest quality standards.

We warmly welcome clients from around the world to visit our factory, where you can see our production processes firsthand and experience our product quality. Please feel free to reach out to us—we are committed to providing you with the best products and services.

Kindly get in touch with us to request a product catalogue.

Reviews

There are no reviews yet.