Description

wpc board cost

Introduction

Wood plastic composite (WPC) boards have gained popularity due to their durability, low maintenance, and eco-friendly nature. They are widely used in construction, landscaping, and interior design projects. However, the cost of WPC boards can vary significantly depending on various factors. This article delves into the key cost factors influencing WPC boards, including material quality, manufacturing process, brand reputation, and market demand.

Material Quality

The quality of materials used in producing WPC boards is a critical factor that impacts their overall cost. High-quality raw materials like recycled plastics and wood fibers ensure better performance and longevity. The use of premium additives for UV resistance, anti-fungal properties, and enhanced durability also adds to the expense. For instance, boards with superior UV protection will likely cost more than those without it. According to a study by the Journal of Building Engineering, higher material quality leads to increased costs but offers long-term savings due to reduced maintenance and replacement needs (source).

Manufacturing Process

The manufacturing process plays a significant role in determining the cost of WPC boards. Advanced production techniques such as extrusion, injection molding, and compression molding require sophisticated machinery and skilled labor, which can increase production costs. Additionally, the efficiency of the manufacturing process affects the final price. Companies that optimize their processes and minimize waste can offer competitive pricing. A report from the Wood Composite Materials journal highlights how improved manufacturing efficiency can reduce costs and improve product quality (source).

Brand Reputation

The reputation and brand of the manufacturer also influence the cost of WPC boards. Established brands often invest heavily in research and development, marketing, and customer service, which can drive up prices. However, these brands typically offer higher quality products and better warranties, justifying the additional cost. On the other hand, lesser-known brands might offer lower prices but may lack the same level of assurance regarding product reliability and after-sales support. Consumers should weigh the benefits of a well-established brand against the potential savings of choosing a less-known option.

Market Demand

The demand for WPC boards in the market can affect their cost. As the popularity of sustainable building materials grows, so does the demand for WPC boards. Increased demand can lead to economies of scale, potentially lowering costs. However, if demand outstrips supply, prices may rise. Market dynamics, such as supply chain disruptions or changes in raw material availability, can also impact pricing. Understanding these market forces helps consumers make informed decisions when purchasing WPC boards.

Pricing Structures

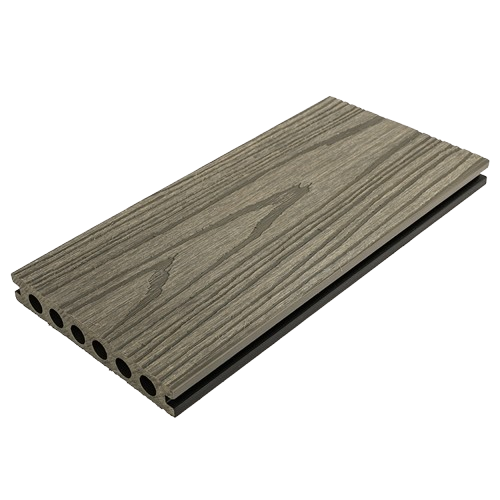

Understanding the pricing structure of WPC boards is essential for making cost-effective choices. Prices can vary based on the thickness, width, length, and surface finish of the boards. For example, thicker boards generally cost more due to the higher volume of material required. Similarly, specialized finishes like embossed patterns or custom colors may come at a premium. Retailers and distributors may offer bulk discounts, further influencing the final cost. It’s advisable to compare prices across different suppliers and consider long-term value when making a purchase decision.

Conclusion

The cost of WPC boards is influenced by a variety of factors, including material quality, manufacturing process, brand reputation, and market demand. While higher-quality materials and advanced manufacturing techniques contribute to higher initial costs, they often result in longer-lasting, more durable products. Brand reputation and market dynamics also play crucial roles in pricing. By understanding these factors, consumers can make informed decisions that balance cost with quality and sustainability.

Reference

Cost Analysis of Sustainable Building Materials: A Case Study of WPC Boards

Impact of Manufacturing Processes on the Cost and Performance of WPC Boards

Baoding Plastroy WPC Products

Why Choose Plastory?

Baoding Plastory New Materials Co., Ltd. is a manufacturer of decorative materials with over 9 years of experience and 56 separate production lines.

Currently, our annual production exceeds 30,000 tons, with products exported to more than 50 countries worldwide.

Plastory is the drafting unit of the WPC National Standards and has obtained certifications such as REACH, ASTM, CE, and FSC. Plastory is dedicated to maintaining consistent quality, focusing on details, and prioritizing customer satisfaction.

Our factory is located in Baoding, Hebei Province, China, with a prime location and convenient transportation access. Baoding is approximately a 1.5-hour drive from Beijing Capital International Airport and just 2 hours away from Tianjin Port, making it easy for global clients to visit and facilitating efficient shipping of goods. Our facility spans a large area, equipped with advanced production equipment and modern testing facilities to ensure that every batch of products meets the highest quality standards.

We warmly welcome clients from around the world to visit our factory, where you can see our production processes firsthand and experience our product quality. Please feel free to reach out to us—we are committed to providing you with the best products and services.

Kindly get in touch with us to request a product catalogue.

Reviews

There are no reviews yet.